Introduction to Brazing

Brazing is a specialized form of soldering used to create strong, non-welded connections capable of withstanding heavy stress. This technique is essential in various industries due to its ability to join dissimilar materials such as metals, ceramics, and glass without melting the base materials.

Why Choose Brazing?

Brazing stands out for its versatility and strength. Unlike welding, brazing does not melt the base materials, which is crucial for applications requiring precision and the joining of different types of materials. This process involves melting a filler metal, which flows into the joint by capillary action, creating a strong bond upon cooling.

Importance of Temperature in Brazing

The success of a brazing operation heavily depends on the correct temperature selection. The goal is to use a temperature high enough to melt the filler metal but low enough to avoid damaging the base materials. Managing heat effects and ensuring minimal interaction between the filler metal and base material are critical.

Pro Iroda Torches: Precision and Performance

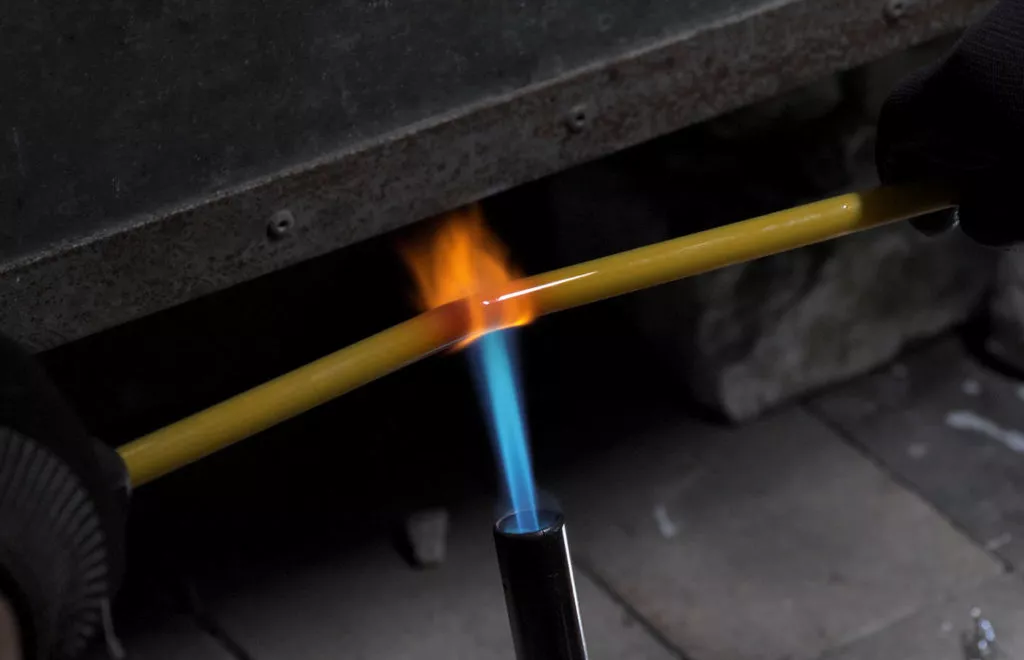

Pro Iroda offers a range of heavy-duty butane torches designed specifically for brazing. These torches feature multi-function gas and air control valves, allowing for precise flame adjustment to match the specific requirements of each brazing job. The choice of fuel—whether MAP-Pro, Propane, or Butane—also influences the brazing process.

Choosing the Right Fuel: MAP-Pro, Propane, or Butane?

- Propane and Butane: These fuels burn at lower temperatures compared to MAP-Pro and are ideal for lighter brazing tasks. They are commonly used in plumbing applications due to their adequate performance for less demanding brazing needs.

- MAP-Pro: This fuel produces a higher flame temperature, which translates to quicker brazing jobs. It is suitable for high-stress applications, such as air conditioner tubing, where a stronger bond is required.

Applications of Brazing with Pro Iroda Torches

Pro Iroda’s heavy-duty butane torches are versatile tools that can handle various brazing applications, from intricate jewelry making and model building to robust plumbing and HVAC repairs. The ability to adjust the flame precisely ensures that these torches can be used for both delicate and demanding tasks.

Advantages of Using Pro Iroda Torches for Brazing

- Precision Control: The multi-function gas and air control valves provide the user with the ability to fine-tune the flame, ensuring optimal temperature and flame characteristics for each specific brazing job.

- Portability: Pro Iroda torches are designed for ease of use in various environments, making them perfect for both professional and DIY applications.

- Efficiency: With higher flame temperatures available from fuels like MAP-Pro, brazing tasks can be completed more quickly, saving time and enhancing productivity.

Step-by-Step Guide to Brazing

- Preparation:

- Clean the Surfaces: Ensure the surfaces to be joined are clean and free from contaminants such as oil, grease, and oxides. Use a wire brush or abrasive pad for cleaning.

- Fit the Pieces Together: Arrange the parts to be brazed in their final positions. The fit should be as close as possible to allow capillary action to draw the filler metal into the joint.

- Choose the Right Filler Metal:

- Select a filler metal compatible with the base materials and the working temperature range of the torch. Common filler metals include brass, silver, and aluminum alloys.

- Set Up the Torch:

- Adjust the Flame: Use the gas and air control valves to achieve the desired flame type. A neutral flame (equal parts of fuel gas and oxygen) is ideal for most brazing applications.

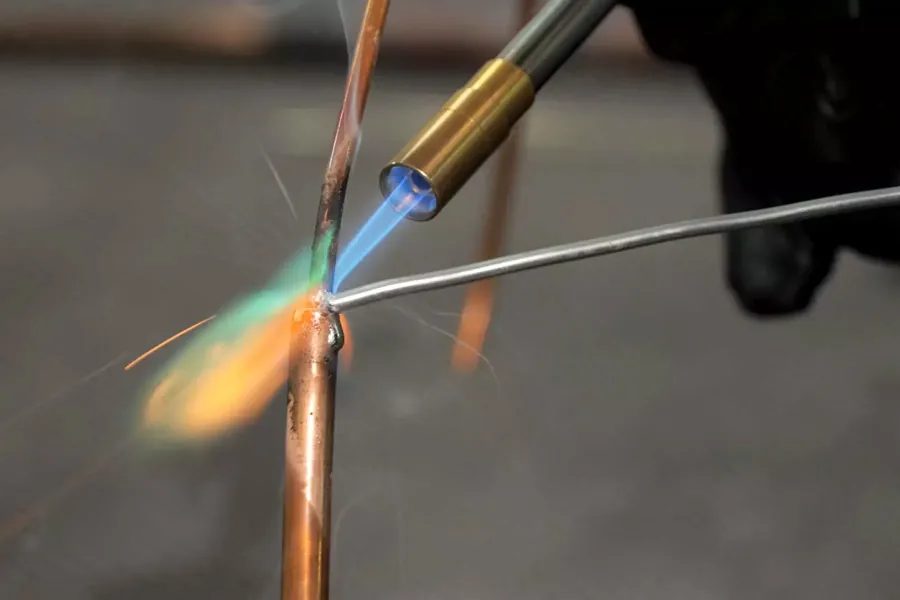

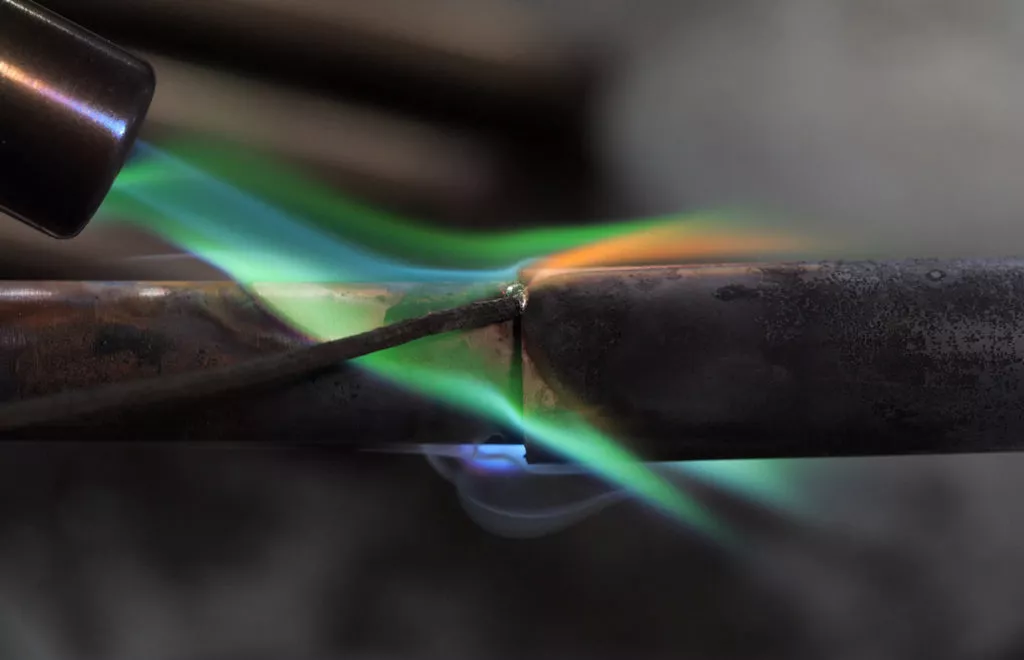

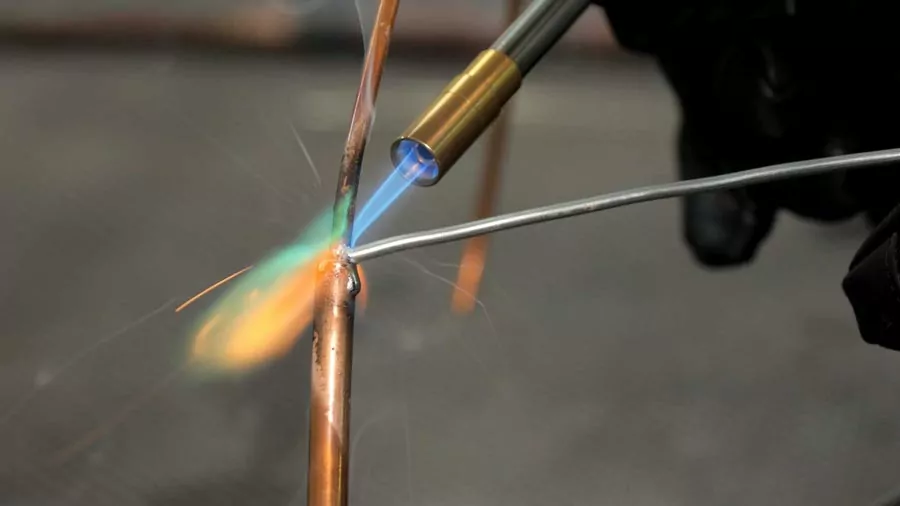

- Heat the Joint:

- Apply Heat Evenly: Heat the joint area evenly to avoid localized overheating. Move the torch in a circular or back-and-forth motion to distribute heat uniformly.

- Watch the Temperature: Monitor the temperature carefully to ensure it reaches the melting point of the filler metal without overheating the base materials.

- Apply the Filler Metal:

- Melt the Filler Metal: Once the joint area reaches the appropriate temperature, apply the filler metal to the joint. The heat from the base materials should be sufficient to melt the filler metal.

- Capillary Action: Allow the filler metal to flow into the joint by capillary action. Ensure complete coverage of the joint area for a strong bond.

- Cooling and Finishing:

- Let it Cool Naturally: Allow the joint to cool naturally. Avoid quenching or applying force during the cooling process to prevent distortion.

- Clean the Joint: After cooling, clean the joint to remove any flux residues and ensure a neat finish.

Things to Watch Out For:

- Overheating: Avoid overheating the base materials, which can weaken the joint and damage the components.

- Inadequate Cleaning: Ensure all surfaces are thoroughly cleaned to prevent weak joints.

- Improper Flame Adjustment: Adjust the flame correctly to avoid oxidizing or contaminating the joint area.

FAQ – Brazing

For those seeking reliable and versatile tools for brazing, Pro Iroda’s range of heavy-duty butane torches offers unmatched precision, performance, and efficiency. Whether you’re working on high-stress applications or lighter tasks, Pro Iroda has the right torch to meet your needs.