It’s not difficult to desolder PCB components with the right equipment, but it’s also very easy to get it wrong and damage the circuit board and other components if you don’t follow the right steps and use the correct equipment. Let’s look at what you need to do to remove a faulty component from a PCB using flux, solder wick and a gas soldering iron.

Why is a gas soldering iron good for desoldering PCB components?

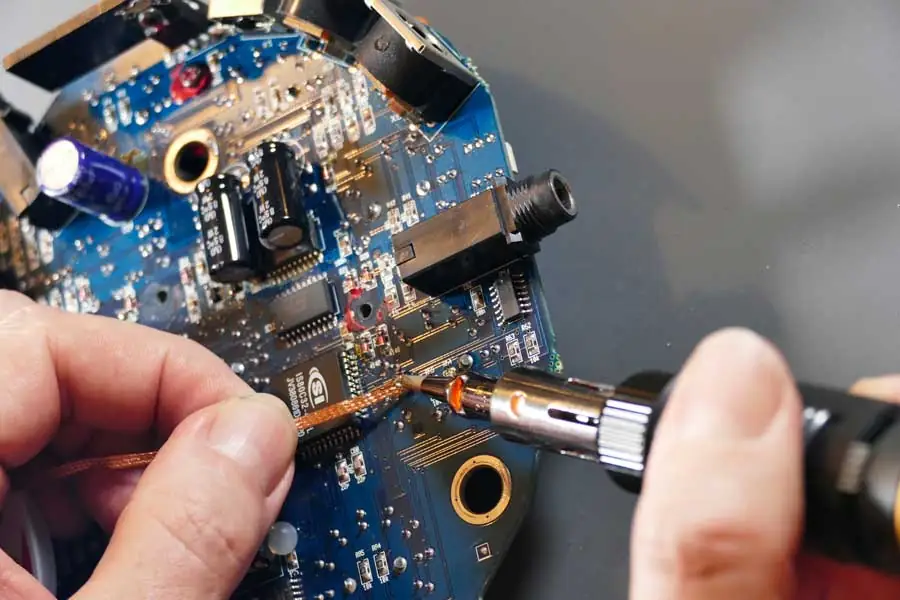

Gas soldering irons like the Iroda SolderPro 110K shown above are good for providing rapid heat to a specific point, which is essential for desoldering PCB components. Portable gas and battery soldering irons are also good for this type of intricate soldering job because they don’t have the trailing lead of a mains powered electric soldering iron. This lets you work easily around other components without worrying about what the cable might be snagging on!

What gear do you need to desolder PCB components?

The picture above shows you the basic gear you need to desolder PCB components from circuit boards. A compact gas soldering iron, some soldering wick (also known as solder braid), and solder flux to improve the flow of the molten solder. Solder flux comes in various forms and is not necessary for the job, but can be helpful if you are working with old, harder solders in speeding up the melting process and getting more solder removed cleanly.

Did I pick the right gas soldering iron for this desoldering project?

This was a challenging project because the components were very close together on a compact board. Older PCBs and less miniaturized devices would be easier to desolder without mishap, but I was able to get the heat where I wanted and for as long as I needed to wick the solder away with the help of the Iroda gas soldering iron.

- Plenty of heat to get the job done quickly

- Acceptable fuel consumption

- Easy ignition and rapid heating to working temperature

The tips supplied are a bit chunky for this scale of work, but not too big, just requiring a bit of close attention. I used the chisel tip as it enables you to rest the flat face on a protruding component leg for reliable heating, whereas pointed and rounded tips can slip off quite easily. This proved to work well, and a benefit of using the largest tip you can is that it transfers heat more efficiently than a smaller tip, so overall this was a good thing.

How powerful a soldering iron do you need to remove solder from a PCB?

Removing solder from a PCB is more difficult than desoldering a solder wire joint or removing wire connections from a potentiometer because your working area is smaller and you run the risk of damaging nearby components or the PCB itself. PCBs are not usually designed to be extremely heat resistant, so you don’t want to use a soldering iron that is too powerful, but you need enough power to remove solder without overheating the PCB underneath.

The Iroda professional gas soldering range has several suitable examples of competent butane gas soldering irons to choose from. The key to successful desoldering on the small scale of PCBs and without damaging the board is to have a soldering iron that is easy to handle, without trailing leads. This is why the Iroda SolderPro 110K I’m using in the image above is a good option for PCB desoldering, getting enough heat to make the solder flow into the wick very rapidly.