Introduction to Butane Soldering Irons

For electronics enthusiasts, field technicians, and DIY repair specialists, having the right tools can make all the difference between project success and frustration. Among the most versatile tools in any serious technician’s arsenal is the butane soldering iron—a portable powerhouse that brings professional-grade heat exactly where you need it, without the limitations of power cords or electrical outlets.

Butane soldering irons represent the perfect marriage of convenience and capability. These cordless tools are powered by liquid butane gas stored within a refillable tank, offering unprecedented freedom of movement while maintaining the precise heat control needed for delicate electronic work. Unlike their corded counterparts, butane-powered tools can go anywhere your projects take you—from automotive repairs in remote locations to field maintenance where power sources are unavailable.

At the forefront of butane soldering technology stands Iroda, a Taiwanese manufacturer with more than 30 years of experience crafting innovative, patented tools that set industry standards. Their flagship product lines—the SOLDERPRO and MICRO-JET Series—have earned global recognition for combining professional-grade performance with exceptional portability. Built on decades of engineering expertise, Iroda’s butane soldering irons exemplify the perfect balance of power, precision, and portability that today’s electronics enthusiasts demand.

How Butane Soldering Irons Work

Understanding the inner workings of these versatile tools helps users maximize their potential and appreciate the engineering that makes them possible. Let’s examine the sophisticated systems that power butane soldering irons:

Fuel Mechanism

The heart of any butane soldering iron is its fuel system. These tools utilize liquid butane—the same gas used in cigarette lighters—stored in a specialized internal tank. The liquid state allows for compact, efficient fuel storage that can deliver sustained heat through a controlled release mechanism.

Iroda’s innovations in this area include their patented LEC (Liquid Electronic Control) cells, which ensure stable fuel pressure and consistent temperature even as the tank depletes. This technology represents a significant advance over earlier butane tools that could suffer from performance fluctuations as fuel levels changed. The LEC system maintains optimal pressure regardless of remaining fuel, ensuring consistent performance throughout the working session.

When it’s time to refuel, the process is remarkably simple:

- Invert the tool completely

- Align refill canister nozzle with the refill valve

- Press firmly for 3-5 seconds

- Allow internal pressure to stabilize before use

This straightforward refueling process takes mere seconds, minimizing downtime and maximizing productivity.

Ignition System

The transformation from liquid fuel to functional heat happens through a sophisticated ignition system. Modern butane soldering irons employ piezoelectric ignition—a mechanical pressure system that generates a high-voltage spark without requiring batteries or external power.

When the user activates the ignition mechanism (typically via a button or switch), a spring-loaded hammer strikes a piezoelectric crystal, generating momentary voltage that creates a spark. This spark ignites a carefully controlled amount of butane gas, initiating the heating process.

Iroda’s safety-focused designs incorporate protective features that prevent accidental ignition and ensure the spark occurs only within the catalytic chamber—never exposing an open flame to the work environment. This attention to safety details allows their tools to be used in sensitive environments where open flames would be prohibited.

Heating Process

What truly distinguishes professional butane soldering irons from simple torch tools is their sophisticated heat management system. Rather than directing an open flame to the work area, these tools utilize catalytic combustion:

- The initial ignition creates a small, contained flame within an internal chamber

- This flame heats a catalytic element (typically platinum or similar high-temperature metals)

- The catalyst continues the combustion process without an open flame

- Heat transfers efficiently to the soldering tip through conductive materials

This catalytic process converts fuel energy to heat with remarkable efficiency while eliminating the dangers of open flames. The result is focused, controlled heat delivery exactly where needed.

Temperature control—crucial for working with various materials—is achieved through precision gas flow regulation. By adjusting the fuel valve, users can modulate output power typically ranging from 20W to 75W equivalent, allowing for temperature ranges from approximately 250°C to 450°C depending on the specific model and tip configuration.

Iroda-Specific Innovations

What sets Iroda apart in this competitive space is their commitment to functionality that extends beyond basic soldering. Their SOLDERPRO Series exemplifies this versatility with multi-function capabilities that transform a single tool into a complete portable workshop:

- Interchangeable Tips: From fine-point precision tips to broad heating surfaces

- Hot Air Functionality: For heat-shrink tubing and surface-mount work

- Heat Tool Applications: For plastic welding and material forming

Additionally, Iroda’s newest innovations include USB-C rechargeable models that offer hybrid flexibility—combining butane power with electric operation when available. This dual-source approach ensures users never face project delays regardless of their working environment.

The table below highlights key specifications across Iroda’s primary product lines:

| Feature | SOLDERPRO Series | MICRO-JET Series | Hybrid Models |

| Power Range | 25-75W | 20-35W | 25-60W |

| Heat-up Time | 10-15 seconds | 7-10 seconds | 5-15 seconds |

| Runtime per Fill | 60-90 minutes | 45-60 minutes | 30-75 minutes |

| Weight | 100-135g | 60-80g | 90-120g |

| Special Features | Multi-tool functions | Ultra-precision tips | Dual power sources |

Why Portability Matters

The liberation from power cords represents more than mere convenience—it fundamentally transforms how and where precision work can be accomplished. Let’s explore what makes this portability so valuable in real-world applications:

Cordless Freedom

The most obvious advantage of butane soldering irons is their complete independence from electrical infrastructure. This freedom proves invaluable across numerous scenarios:

- Remote field repairs where electrical outlets aren’t available

- Automotive electrical work in parking lots or roadside situations

- Installation projects in partially constructed buildings

- Outdoor repair situations during power outages

- High-altitude or wilderness projects far from infrastructure

This cordless capability isn’t merely convenient—it often makes the difference between completing a repair on-site versus the costly alternative of transporting equipment to a workshop. For professionals whose reputation depends on rapid resolution of problems, this mobility translates directly to customer satisfaction and business success.

Rapid Deployment

When urgent repairs are needed, the time required to set up equipment becomes a critical factor. Traditional electric soldering stations typically require:

- Finding a suitable power outlet

- Unpacking and assembling components

- Waiting 1-5 minutes for heating

- Allowing additional time for temperature stabilization

In contrast, Iroda’s butane soldering irons offer nearly instantaneous operation:

- Remove protective cap

- Activate ignition

- Begin working within 10-30 seconds

This dramatic reduction in setup time—particularly the elimination of warm-up waiting—can save crucial minutes during time-sensitive repairs. For service technicians billing by the hour or working against tight deadlines, these efficiency gains compound across multiple daily service calls.

Compact Design

Modern electronics increasingly require service in confined spaces where bulky equipment creates additional challenges. The integrated, self-contained nature of butane soldering tools provides significant advantages in spatial efficiency:

- No separate power units or controllers

- No cables to manage or protect

- Reduced overall footprint in the workspace

- Simplified storage and transport

Iroda’s MICRO-JET Series exemplifies this space-saving design philosophy with ultra-compact profiles specifically engineered for work in tight enclosures and densely packed electronic assemblies. Their streamlined form factors allow access to connection points that would be unreachable with larger tools.

Real-World Use Cases

The practical benefits of butane soldering irons become most apparent through specific application examples:

HVAC Technicians frequently need to repair control boards and wire connections in awkward positions—often in attics, crawlspaces, or outdoor units. Iroda’s butane tools allow them to complete these repairs without running extension cords or repeatedly climbing ladders to reach power sources.

Remote Communications Installers working on tower-mounted equipment face extreme challenges with conventional power tools. Butane soldering irons provide the perfect solution for high-elevation repairs where power access is impossible and weight considerations are critical.

RC Vehicle Enthusiasts performing trackside repairs during competitions benefit from the ability to quickly fix damaged connections without returning to pit areas. The rapid heat-up time and precision tips of the MICRO-JET Series make these emergency repairs possible within tight time constraints.

Jewelry Artisans working at outdoor craft fairs can perform on-site sizing and custom work without requiring dedicated electrical setups, expanding their service capabilities while minimizing equipment needs.

Butane vs. Electric: Key Comparisons

When selecting tools for electronic work, understanding the relative strengths of different technologies helps ensure the right choice for specific applications. The comparison chart below highlights the key differences between butane and electric soldering solutions:

| Feature | Butane Soldering Irons (Iroda) | Electric Soldering Irons |

| Portability | Completely cordless, usable anywhere | Requires proximity to power outlets |

| Heat-Up Time | 10-30 seconds | 1-5 minutes |

| Temperature Range | Adjustable from 250-450°C | Often fixed or limited adjustment range |

| Temperature Stability | LEC technology maintains consistency | May fluctuate with voltage variations |

| Durability | Rugged construction, fewer mechanical failures | Heating elements and cords prone to damage |

| Runtime Limitations | 45-90 minutes per fuel fill | Unlimited while powered |

| Environmental Adaptability | Functions in any climate/altitude | May require voltage adaptors in different regions |

| Multi-functionality | Tips for soldering, hot air, heat shrink | Generally single-purpose tools |

| Cost Efficiency | Higher initial investment, economical fuel costs | Lower initial cost, higher long-term electricity usage |

| Maintenance Requirements | Periodic cleaning and refueling | Tip replacement and cord maintenance |

This comparison reveals that while both technologies have their place in a complete toolkit, butane soldering irons offer distinct advantages in situations prioritizing mobility, rapid deployment, and versatility across different operating environments.

Safety and Maintenance Best Practices

To ensure optimal performance and longevity from butane soldering tools, proper safety protocols and maintenance practices are essential. Following these guidelines will maximize both safety and tool lifespan:

Safe Operation

Working with any heat-generating tool requires appropriate caution. When using butane soldering irons, observe these important safety practices:

- Always work in well-ventilated areas to prevent accumulation of combustion byproducts

- Maintain awareness of the tool’s temperature—tips can reach 450°C

- Use appropriate surfaces for resting the tool during operation

- Allow sufficient cooling time before storing the tool

- Keep butane tools away from flammable materials and chemicals

- Never leave an ignited tool unattended

Iroda’s commitment to user safety is evident in their incorporation of thoughtful safety features across their product lines. These include secure safety locks that prevent accidental ignition, protective flame guards that contain the catalytic process, and ergonomic designs that minimize user fatigue during extended operation..

Maintenance Tips

Proper maintenance not only extends tool life but ensures consistent performance. Follow these guidelines to keep your butane soldering iron in optimal condition:

Refilling Procedure:

- Ensure the tool is completely cool

- Purge remaining gas pressure by pressing the refill valve with a small tool

- Invert both the tool and butane canister completely vertical

- Press canister nozzle firmly into refill valve for 3-5 seconds

- Wait 3 minutes before igniting to allow gas stabilization

Tip Care:

- Clean tips regularly using brass sponges (never abrasive materials)

- Apply small amounts of solder to tips before storage (“tinning”)

- Replace damaged or worn tips promptly

- Use appropriate tip shapes for specific applications

Long-term Storage:

- Ensure complete cool-down before storage

- Apply protective caps to prevent tip damage

- Store in moderate temperature environments

- For extended storage periods, consider emptying fuel tank

- Troubleshooting Common Issues:

| Problem | Possible Cause | Solution |

| Difficulty igniting | Empty fuel tank | Refill according to procedure |

| Air in fuel line | Purge system by attempting multiple ignitions | |

| Damaged ignition system | Contact service center for repair | |

| Weak flame/heat | Low fuel | Refill tank completely |

| Clogged catalyst | Allow complete burnout at max temperature | |

| Incorrect gas adjustment | Reset to manufacturer specifications | |

| Inconsistent temperature | Improper gas regulation | Adjust regulator to midpoint and fine-tune |

| External air currents | Use in more protected environment | |

| Fuel contamination | Empty tank completely before refilling |

Applications Beyond Electronics

While electronic repair represents the most common application for precision soldering tools, Iroda’s butane technology opens possibilities across numerous other fields. These versatile tools have found successful application in surprising domains:

Automotive Repairs

Modern vehicles contain dozens of electronic control units and hundreds of feet of wiring—all subject to vibration, temperature extremes, and corrosion. Butane soldering irons prove invaluable for:

- Field repairs of broken sensor connections

- Application of heat-shrink tubing for waterproof connections

- Maintenance of trailer wiring harnesses

- Emergency fixes for critical electrical components

- Dashboard and instrumentation repairs

The portability of these tools makes them perfect for roadside assistance professionals and mobile mechanics who must complete repairs wherever vehicles become disabled.

Jewelry Making

The precision temperature control and fine-point tips available for Iroda tools make them surprisingly suitable for jewelry work:

- Low-temperature silver soldering

- Setting small stones with precision heating

- Customizing pieces at craft shows and markets

- Creating wire-wrapped designs with soldered joints

- Repair of fine chains and settings

Many jewelers appreciate the freedom from electrical cords when demonstrating techniques at shows or working in studio environments with limited power access.

Emergency Repairs

When unexpected breakages occur away from workshop environments, butane soldering capabilities can transform impossible situations into simple fixes:

- Repairing broken tent poles or camping equipment

- Fixing crucial gear during outdoor expeditions

- Temporary plumbing repairs using soft solder

- Restoring electrical connections during power outages

- Mending broken eyeglass frames

The SOLDERPRO’s multi-tip functionality allows it to serve as a compact emergency repair kit for adventurers, travelers, and outdoor enthusiasts facing equipment failures in remote locations.

Artistic Applications

Creative practitioners have discovered unique applications for the precise heat control offered by butane tools:

- Encaustic painting techniques requiring targeted heat

- Creating sculptural elements with thermoplastics

- Detail work on mixed-media art installations

- Pyrography (wood burning) with specialized tips

- Foil application in decorative arts

The portable nature of these tools allows artists to work in inspirational outdoor settings or demonstrate techniques at workshops without complex setup requirements.

Conclusion

The remarkable versatility and unmatched portability of butane soldering irons have revolutionized how technicians, hobbyists, and professionals approach precision heating tasks. As we’ve explored throughout this article, these tools offer distinct advantages that make them indispensable for work situations where mobility, rapid deployment, and multi-functionality are priorities.

Iroda’s three decades of engineering expertise have produced butane soldering solutions that consistently exceed industry standards for performance, reliability, and safety. Their patented technologies—from the innovative LEC cells that ensure temperature stability to their interchangeable tip systems that transform single tools into complete portable workshops—demonstrate the company’s unwavering commitment to advancing portable heat tool technology.

Whether you’re a professional field technician requiring reliable tools for mission-critical repairs, a DIY enthusiast working on projects beyond electrical outlet range, or a creative practitioner exploring new artistic techniques, butane soldering technology offers capabilities that simply cannot be matched by traditional corded alternatives.

For those ready to experience the freedom and flexibility of professional-grade butane soldering tools, explore the complete range of Iroda’s innovative solutions at pro-iroda.com, where Taiwanese engineering excellence meets global performance standards in tools designed for today’s mobile professionals.

FAQs

Q: How long does a butane tank last on Iroda soldering irons?

A: Most Iroda models provide 60-90 minutes of continuous use per tank fill, though actual runtime varies based on temperature settings and environmental conditions. The efficiency of Iroda’s catalytic systems extends operating time considerably compared to simple torch-type tools.

Q: Are Iroda tips compatible with other brands of soldering irons?

A: For optimal performance and safety, always use Iroda-certified tips designed specifically for your model. These tips are engineered with precise thermal characteristics and fitting tolerances that ensure proper heat transfer and secure attachment during operation.

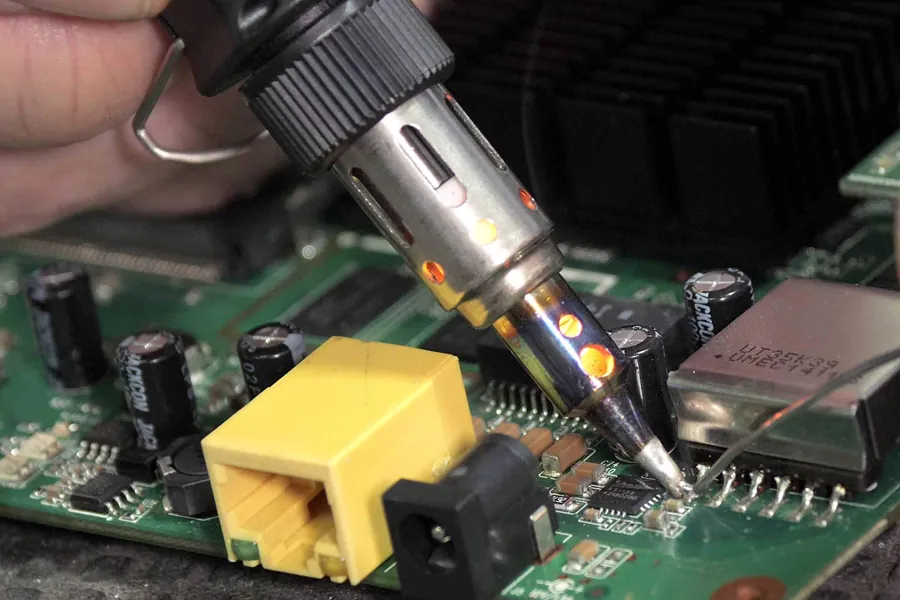

Q: Can I solder circuit boards with butane irons?

A: Absolutely! Iroda’s MICRO-JET series is specifically designed for precision electronics work. When using the appropriate fine tips and adjusting to lower temperature settings, these tools provide the controlled heat necessary for delicate PCB work without risking component damage from excessive temperatures.

Q: Is it safe to transport butane soldering irons on airplanes?

A: Most transportation authorities prohibit butane tools in carry-on luggage. For checked baggage, the tool must be completely emptied of fuel and securely packaged. Always check specific airline regulations before traveling, as policies vary by carrier and region.

Q: How do I know when my butane soldering iron needs refilling?

A: Declining flame intensity and reduced temperature are the primary indicators of low fuel. Most Iroda models also feature transparent fuel windows that allow visual confirmation of remaining butane levels. As best practice, refill before beginning important projects to ensure uninterrupted work.

Q: Can butane soldering irons work in cold environments?

A: Yes! Unlike some battery-powered tools that lose efficiency in cold temperatures, butane soldering irons maintain full functionality across wide temperature ranges. The catalytic heating system provides consistent performance even in below-freezing conditions, making them ideal for winter field repairs.