The Iroda SolderPro 110K gas soldering iron proves to be a good choice for heatshrink solder seal butt connectors, with consistent high heat output and optional heat shield. You can even use it on its built-in stand to give you convenient, hands-free operation.

Why do I use the Iroda SolderPro 110K gas soldering iron for heat shrink solder connectors?

The Iroda SolderPro 110K from the Iroda Professional range is my go-to choice for solder seal heat shrink solder connectors for several reasons. It provides the right level of heat output in a convenient, easy to handle size. The heater tip is well designed for consistent heating and the optional heat shield helps to focus and maintain the heat flow around the solder but joint.

An additional useful feature of the Iroda SolderPro 110K gas soldering iron for heat shrink solder splices is that it is very stable when resting on its built-in fold-out stand. This enables me to focus on the heat shrink wire connector and gives both hands free to keep the joint steady while soldering. This is particularly useful when working on small benchtop projects.

What is a heat shrink solder seal wire connector?

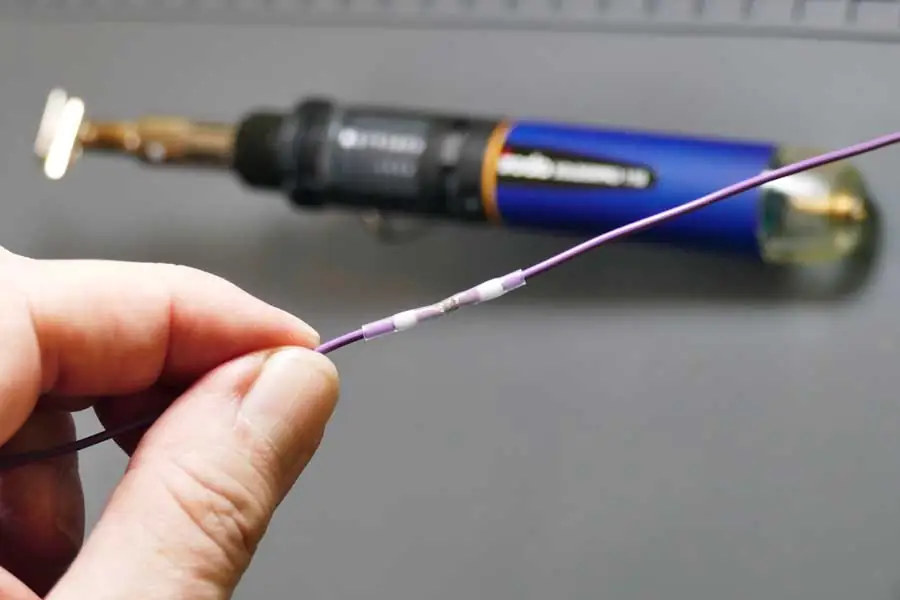

Heat shrink solder seal wire connectors (also known as solder butt connectors) combine soldering wire together and sealing the connection against water and oxidation in a single process. When heated, at first the plastic tube shrinks and sticks to the wires inside it, sealing the joint. Continued heating melts a central ring of solder that flows into the wires to make a secure electrical connection.

Best practice tips for heat shrink solder connector use

You will normally need to strip about ¼” / 6mm of insulation from the wires, but this might vary depending on the size of the connector. Some wire insulation should remain inside the heat shrink of the connector to ensure a good seal. When you insert the wires, check that the wires merge in the middle of the connectors inside the central band of solder, the solder ring.

- Strip off ¼” / 6mm of insulation from the ends to be connected

- Fit a heat shield to your soldering iron if you have one

- Heat the ends first to seal the joint

- Heat the center to melt the solder

- Wait for the solder to cool before testing

If you are using a curved heat shield on your gas soldering iron, make sure you fit it before igniting the soldering iron! The tip gets hot very quickly so you can’t put it on afterwards until it has cooled down again or you run the risk of burning yourself. Start heating at the ends of the connector with the Iroda SolderPro 110K with the heating tip connected and see the transparent tube shrink to grip the wire insulation. Heating from the ends also activates adhesive inside the tube with some brands of solder seal connector.

Apply heat directly to the center where you see the solder ring and watch to see it melt and spread into the wires, don’t stop until you see the solder has melted into the wires, which usually happens quite suddenly when the wires reach the melting temperature of the solder around them. It’s very important that the solder melts into the wire bundle as this creates the strong electrical bond. Stop heating immediately after this happens to avoid burning the insulation.

Wait for the connection to cool completely before handling it. As the solder cools it will harden in place and the sleeve will also tend to harden up as the adhesive sets to create a waterproof seal. Test the connection with a multimeter for conductivity and give it a light tug with your hands to make sure the solder joint is good. A dry joint, where the solder has not stuck to the wire, will tend to move slightly.

What’s the verdict on the Iroda SolderPro 110K for solder seal wire connectors?

I find the Iroda SolderPro 110K a very good tool for solder seal wire connectors. The combination of compact size, high and easily controlled heat output and the built in stand for hands-free operation add up to a very functional package for all types of heat shrink uses. The additional option of the curved heat shield is a bonus for this type of soldering work.