Understanding Soldering Iron Tip Maintenance

Soldering iron tips are critical for effective soldering, and their maintenance directly impacts soldering quality. A well-maintained tip ensures proper heat transfer, essential for forming reliable solder joints. Oxidation, the formation of iron oxide on the tip, is a common issue that hinders heat transfer and causes solder to ball up rather than flow smoothly.

Our detailed video guide will walk you through the essential steps and tips to effectively clean and maintain your soldering iron tips:

Items Needed

60/40 Rois Solder Core Ø 1.0mmV

Steps for Cleaning Your Soldering Iron Tips

- Preparation

- Heat the Soldering Iron: Before starting the cleaning process, heat your soldering iron to the appropriate temperature. A hot soldering iron makes cleaning more effective as it allows the removal of oxidation and contaminants.

- Apply Rosin Core Solder

- Use 60/40 Rosin Core Solder: Apply a small amount of 60/40 rosin core solder to the tip of the heated soldering iron. The rosin core acts as a flux, helping to remove oxidation and contaminants from the tip.

- Wipe with a Damp Sponge

- Clean the Tip: Gently wipe the tip of the soldering iron on a damp sponge. This removes excess solder and any remaining contaminants. Ensure the sponge is damp, not soaking wet, to avoid damaging the tip.

- Repeat if Necessary

- Repeat the Process: If the tip is still dirty or oxidized, repeat the process of applying rosin core solder and wiping with a damp sponge until the tip is clean.

- Tin the Tip

- Apply Fresh Solder: After cleaning, apply a fresh layer of solder to the tip (known as tinning). This prevents oxidation and ensures the tip is ready for the next use.

Tips for Maintaining Your Soldering Iron Tips

- Regular Cleaning: Clean the tip after every use to prevent the buildup of oxidation and contaminants.

- Proper Storage: Store the soldering iron in a dry place and use protective caps if available to shield the tip from air exposure.

- Temperature Control: Avoid using the soldering iron at excessively high temperatures for prolonged periods, as this accelerates oxidation and degrades the tip.

- Use Quality Solder: Using high-quality solder with flux can help maintain the tip’s condition and improve soldering efficiency.

- Avoid Contaminants: Keep the tip free from contaminants by not using it on dirty surfaces or materials that can leave residues.

Common Issues and Solutions

- Oxidation

- Issue: Oxidation forms on the tip, hindering heat transfer and causing solder to ball up.

- Solution: Regularly tin the tip with fresh solder and clean it using rosin core solder and a damp sponge.

- Tip Wear

- Issue: The tip wears down over time, leading to poor heat transfer and inefficient soldering.

- Solution: Replace the tip when it shows significant signs of wear and regularly maintain it to prolong its life.

- Contamination

- Issue: The tip becomes contaminated with residues from dirty surfaces or low-quality solder.

- Solution: Use high-quality solder and keep the tip clean by wiping it on a damp sponge during use.

Advanced Cleaning Techniques

For heavily oxidized or contaminated tips, advanced cleaning techniques may be necessary:

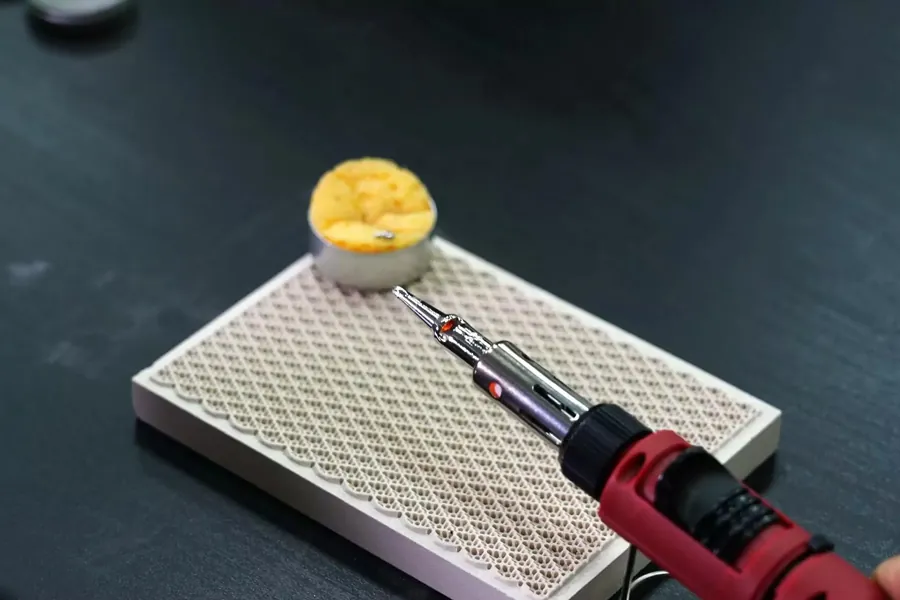

- Tip Tinner/Cleaner: Use a tip tinner/cleaner compound to clean and re-tin heavily oxidized tips. This compound contains a mixture of solder and flux designed to restore the tip’s condition.

- Brass Tip Cleaner: A brass tip cleaner can be used as an alternative to a damp sponge. It effectively removes oxidation without causing thermal shock to the tip.

FAQ – Cleaning Your Soldering Iron Tips

About Iroda Soldering Irons

Pro Iroda offers a range of professional-grade soldering irons known for their durability, efficiency, and precision. Their products, such as the SOLDERPRO 100, 110, 120, and 150, are designed to meet the needs of both hobbyists and professionals. These soldering irons feature advanced temperature control, quick heat-up times, and high-quality tips that ensure reliable and consistent performance. With Pro Iroda’s soldering irons, you can achieve excellent results in all your soldering projects, backed by a brand known for its commitment to quality and innovation.

Conclusion

Regular cleaning and proper maintenance of your soldering iron tips are essential for effective soldering and extending the life of your tools. By following these steps and tips, you can ensure your soldering iron performs optimally every time.