Heat shrink solder seal connectors, also known as solder splices and solder butt connectors, are a very easy way to make waterproof soldered wire connections using a gas soldering iron, gas torch or other direct heat source. Let’s have a look at how they work and identify some Iroda professional gas soldering irons that you can use to make heat shrink solder seal connections really straightforward.

Do you need a soldering iron for heat shrink solder seal connectors?

You can use any direct heat source that generates enough heat to shrink the outer casing and melt the solder into the wires. You don’t need to use a soldering iron for this job, you could use a small gas torch. However, there are very good reasons to use a soldering iron, and specifically a gas soldering iron like the Iroda SolderPro 110K, for heat shrink solder seal connectors.

How do heat shrink solder seal butt connectors work?

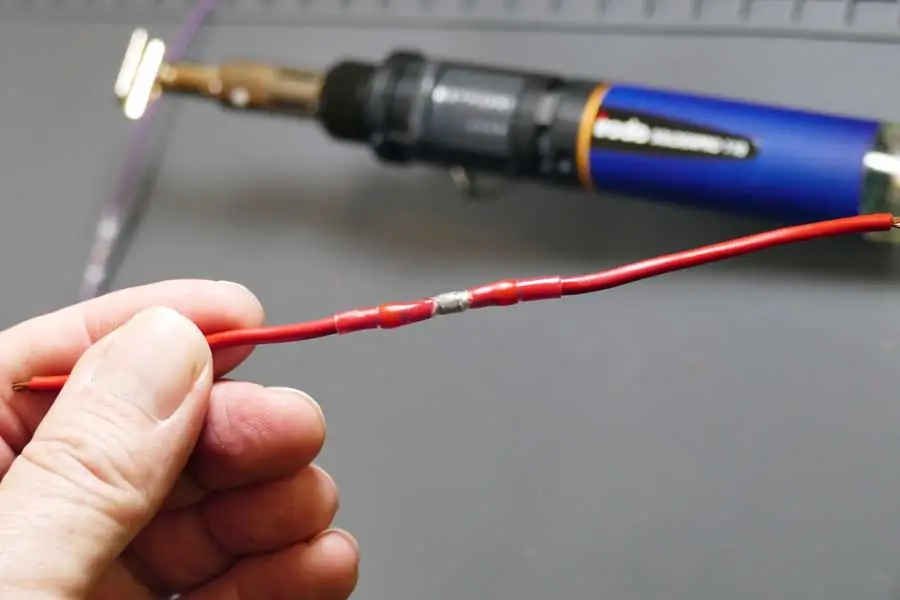

This is really all in the name, which describes what they do. A heat shrink solder seal butt connector uses heat to make a waterproof and conductive seal between the ends of two pieces of electrical wire. The wire ends are inserted into the connector which is then heated up to solder the wires together and form a heat shrink impervious seal over the soldered connection.

Why is a gas soldering iron a good choice for solder seal connectors?

A gas soldering iron with a suitable heat blower adapter tip is a good choice for heat shrink solder seal connectors because it provides precise, directional heat without flame. This is very important to avoid charring or even igniting the connector heat shrink tubing, and melting the wire insulation on each side of it. A gas torch can do the job, but can also damage things close to the soldered butt connection you are trying to make. Gas torches are also more likely to burn the insulation than a gas soldering iron.

What’s the process for using heat shrink solder seal connectors?

There are seven stages to joining two pieces of wire using heat shrink solder seal connectors. You will need to have connectors of the right size to match the wires you are connecting, and also a suitable heat source. The Iroda SolderPro 110K with a heating tip fitted instead of a soldering tip is perfect for this job. An electrical testing meter will enable you to check that the connection is good when you are finished.

- Strip the insulation from the wire ends

- Insert the wires from each end of the connector

- Apply heat, starting with the ends

- Apply heat to center to melt the solder ring

- Wait until the solder has melted and flowed into the wires

- Allow the connection to cool down

- Test for electrical conductivity & physical strength of the join

Iroda professional gas soldering irons for solder seal wire connections

The Iroda professional gas soldering range has many butane gas soldering irons that are perfect for heat shrink solder seal wire connections. When you are looking for a lot of heating power in a small package with accessories that help you with soldered butt joint wire splicing, the Iroda range is hard to beat, and includes a range of useful accessories.

Why is a heat shield a good accessory for your gas soldering iron?

A heat shield that fits around the connection and contains the heat will speed up the process by distributing the heat more evenly, and will also protect the surrounding area from the heat from the gas soldering iron. It’s not essential to have a heat shield, and it does restrict your ability to ‘work around’ the connector, but for most heat shrink jobs it helps to give you a consistent, professional looking result.

The Iroda SolderPro 110K with heater tip for heat shrink solder seal connectors

Remember if you are choosing a gas soldering iron for heat shrink solder seal connection or applying standard heat shrink to soldered connections you need to have a suitable heater tip for your gas soldering iron. The Iroda SolderPro 110K comes with a heater tip as standard in the boxed package. The Iroda heat shield is available separately, easily slips over the heater tip and is held in place by friction.