Enameling demands you can heat the metal base to a red heat to melt the glass powder successfully. You can use a powerful gas soldering iron for enameling if you can also use it as a gas torch. Not all gas soldering irons have the capability to be used as a gas torch for enameling, so if you are looking to use a gas soldering iron for enameling you need to be sure it is powerful enough and can be used to generate a hot flame.

How do you enamel with a gas soldering iron?

There are several steps to successful enameling with a gas soldering iron, but before you start you need to be sure that your gas soldering iron is powerful enough to melt the enamel, and also check that it can be used as a gas torch, since you will need to use a flame to heat your enameling project.

What are 7 steps for enameling with a gas soldering iron?

- Prepare the surface of your enameling project with fine sandpaper and cleaning fluid

- Paint the blank with a flux liquid or enamel base

- Sift colored enamelling glass powder onto the blank to make an even layer

- Transfer the blank to a heating grid with the side to be enameled uppermost

- Ignite your gas soldering iron and play the flame onto the underside of the metal blank

- Wait until the blank glows orange and all the enamel has melted

- Remove the heat and allow the enamel to cool before touching it

Clean your copper or silver blank and ensure it is dry before proceeding

When you enamel you melt glass onto a metal surface, this is usually copper or silver. Copper is commonly chosen for jewelry enameling as it is not expensive, and it is easy to heat it to the correct temperature. The surface to be enameled needs to be clean and dry, you can clean it with acetone before you start.

Use liquid enameling flux after abrading the surface with fine grit sandpaper

Surface preparation is very important to make the molten glass flow evenly, adhere to the surface and get the finish you want, so cleaning the surface and lightly abrading it with a fine sandpaper is standard procedure. You can then add a coating of liquid flux that helps the enamel powder to stick evenly.

Apply your choice of enamel color and pattern to your metal blank

If you want to have a very even layer of enamel, you should use a fine mesh screen to sift the enamel powder onto the blank. You can also make patterns in the enamel or move it around with a small, dry paintbrush or dental tools. Any irregularities in the surface will usually remain in the finished glaze, so you can create a textured surface.

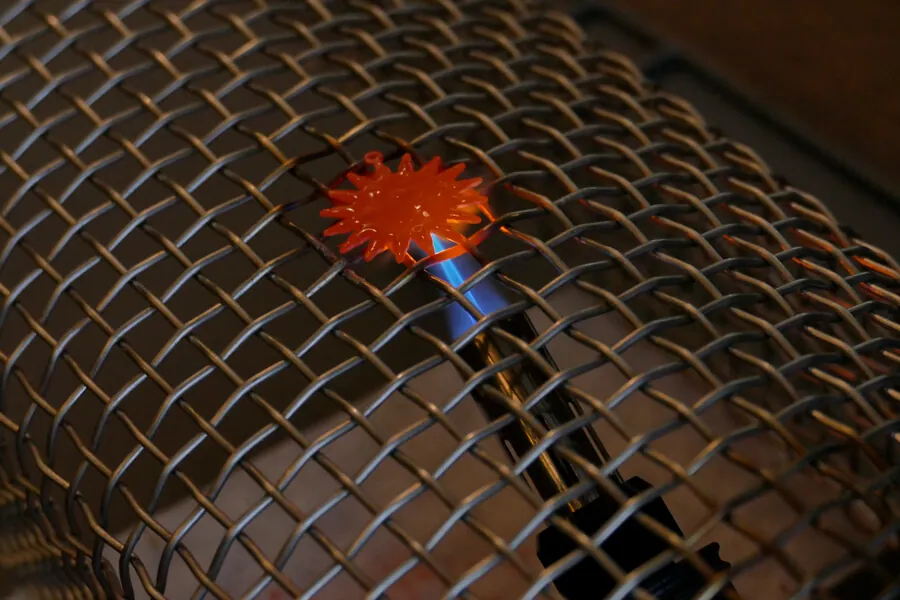

Place your powder coated blank onto the enameling mesh support

Carefully transfer your powder coated blank onto the mesh grid of your enameling station. This usually consists of an arch-shaped tunnel of stainless steel mesh with a protective fireproof brick underneath. The heat will be applied from underneath, not from the top surface.

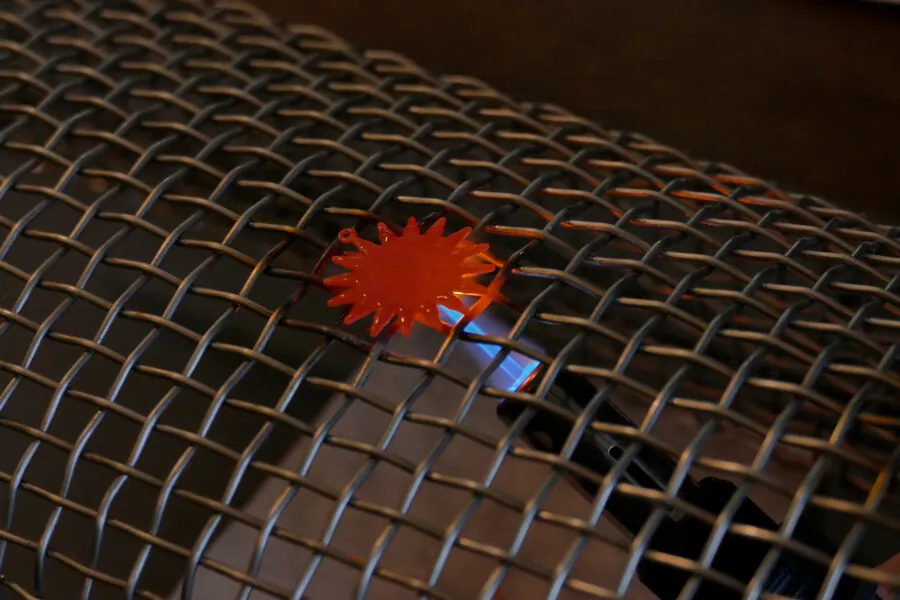

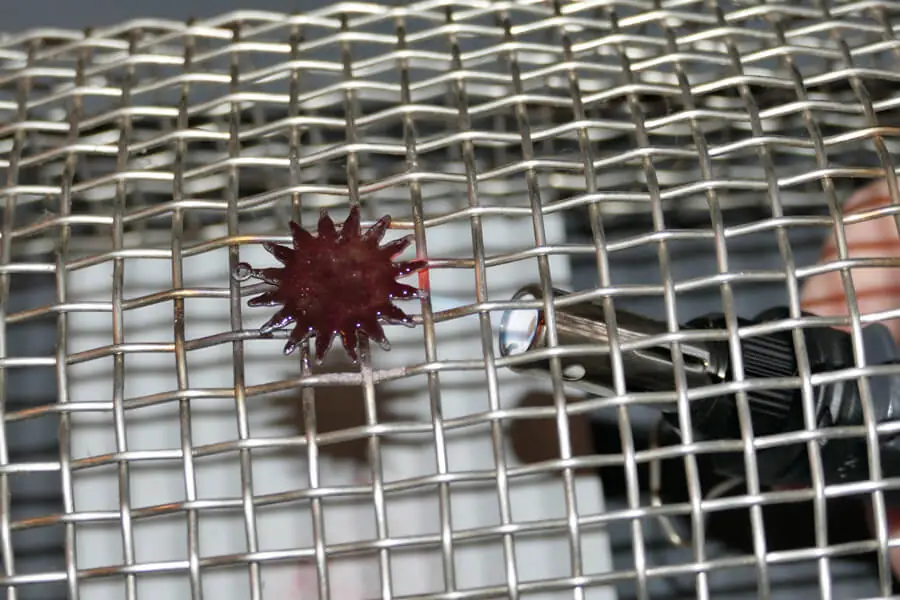

Heat the metal blank from underneath with your gas soldering iron

As you heat the metal blank from underneath, you will notice the enamel will usually darken as it starts to melt, this is normal. You need to keep applying heat evenly to avoid hot spots as you will probably want the enamel powder to melt uniformly across the piece.

Keep heating until the enamel and metal blank are glowing orange

When the enamel and metal blank are glowing orange you will see the enamel powder melting and forming a glazed surface. Keep heating until this point, even though you will be unable to see the original color of the glaze. That will return when it cools down.

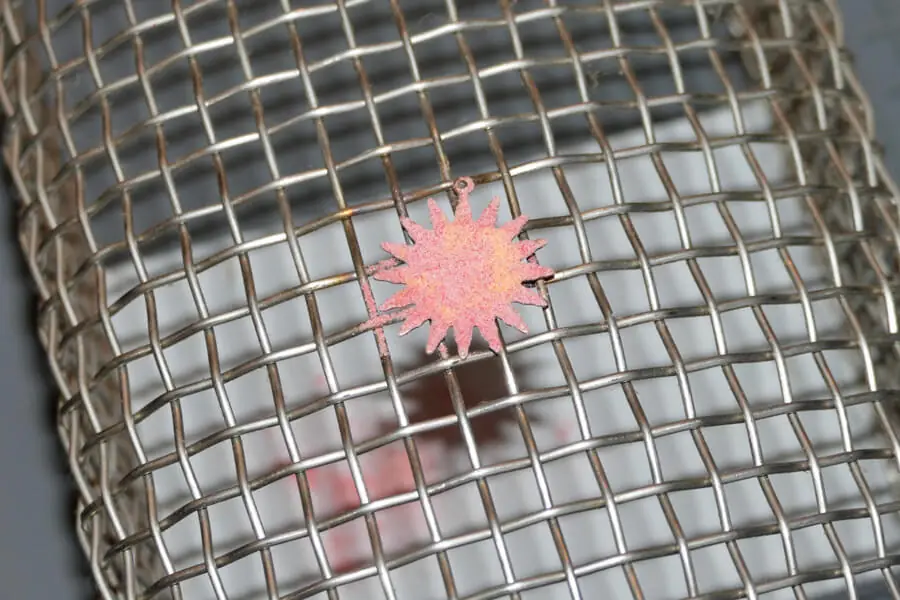

Remove the heat and allow the piece to cool before touching it

The final result for this trial piece was quite dark, as you can see on the left in the picture above, but the enamel fused well across the surface as you can see when you compare it to the original copper blank seen next to it. A piece this size will take 5-10 minutes to cool down after you remove the heat, so resist the temptation to immediately try and pick it up!

Why are Iroda gas soldering irons a good choice for enameling?

Enameling requires a precisely controlled heat source with a well formed, high temperature flame, and that is why Iroda gas soldering irons are a good choice for enameling. The Iroda SolderPro 110K we’ve used here gives you a high heat output in a small, portable, package that enables you to direct the heat accurately to ensure even heating of your enamel jewellery project.

The Iroda SolderPro professional range of gas soldering irons can be used as direct flame torches as well as soldering irons, making them very versatile tools for jewelry and craft projects as well as electrical and electronic soldering tasks.