We thought we would try some jewelry enameling projects using the Iroda SolderPro 110K gas soldering iron in gas torch mode, with the soldering tip removed. We were impressed with the precise heat control and high heat generation capabilities of this compact, powerful gas soldering iron, which is clearly well suited to jewelry enameling tasks.

How do you set up the SolderPro 110K gas soldering iron for enameling?

A feature of the Iroda SolderPro 110K gas soldering iron that makes it usable for enameling is that you can remove the tip and use the SolderPro 110K as a gas torch. The tuned flame is ideal for jewelry enameling, with a focused flame tip that indicates the zone of maximum heat generation. As you can see from the finished piece in the picture above, this makes the SolderPro 110K gas soldering iron an effective tool for enameling work.

What enameling tasks did we do with the Iroda SolderPro 110K gas soldering iron?

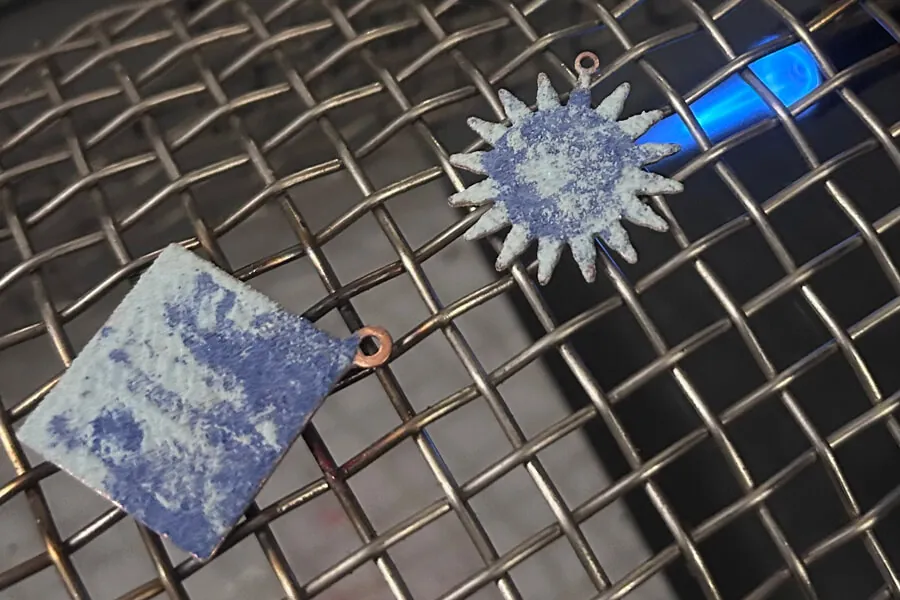

We’ve done an overview of enameling with gas soldering irons, which looked at the basic principles, and for this project we decided to make two small enamel pieces that would be joined together and attached to a silver chain to make a necklace. In the picture above you can see the enamel powder has been layered on both pieces and we’re just starting to heat the first one with the Iroda SolderPro 110K gas soldering iron in gas torch configuration.

High heat output makes it easy to get enamel pieces to the correct temperature

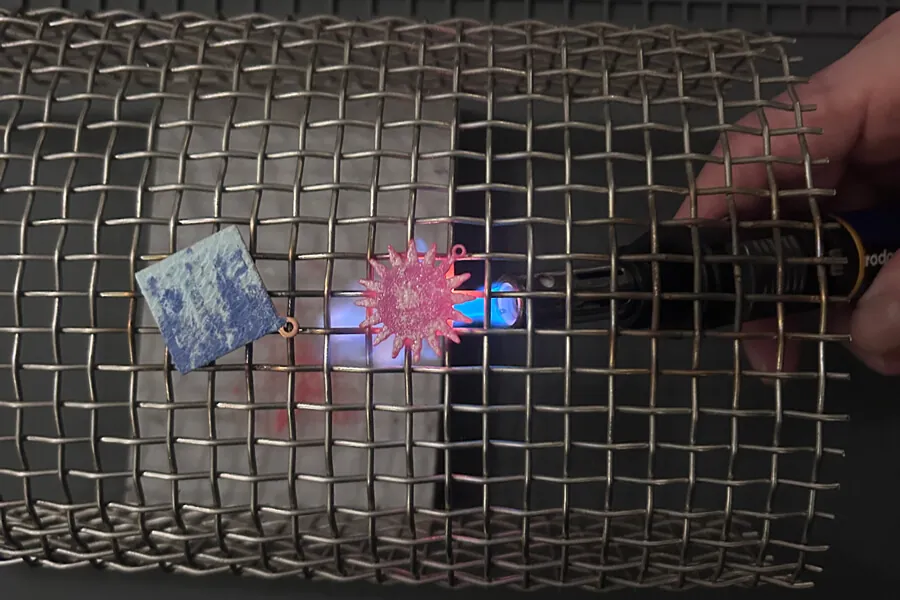

In the picture above the first, star-shaped, piece is reaching the correct temperature for the enamel to melt, heated from below with the Iroda SolderPro 110K. It didn’t take long to get to this stage because the Iroda gas soldering iron is capable of a very high heat output.

How do you enamel with the Iroda SolderPro 110K gas soldering iron?

- Remove the soldering tip from your SolderPro 110K gas soldering iron

- Finely sand and clean the surface of your enameling blank

- Optionally, you can also prepare the blank with liquid flux or an enamel base layer

- Sift powdered enamel onto the metal blank in the colors and patterns you want

- Place the blank on a heating mesh with enamel side on top

- Apply the tip of the flame of your gas soldering iron to the underside of the metal blank

- Heat the blank until it glows orange and the enamel has melted

- Turn off your gas soldering torch and wait for the enamel to cool

- Add any finishing touches to complete your enamel jewelry project

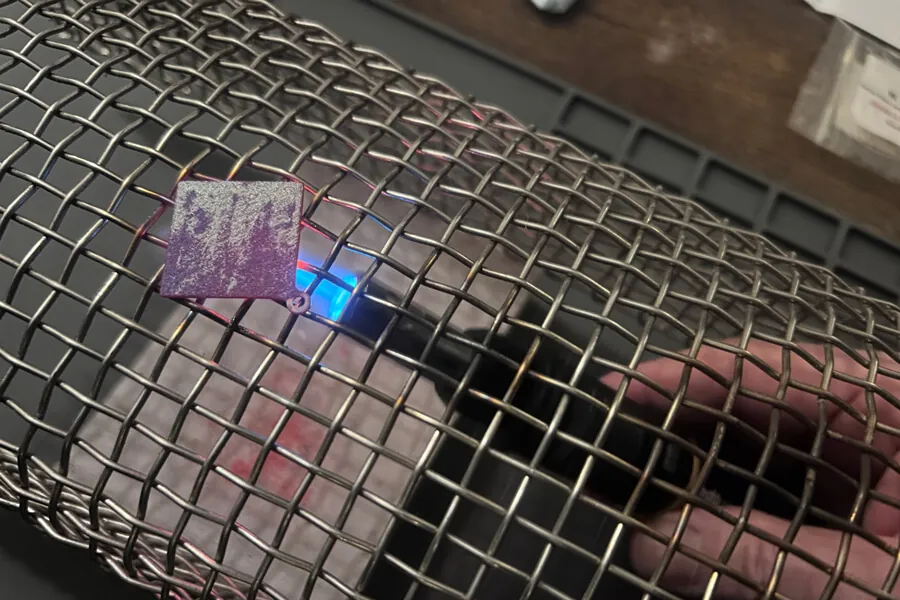

The SolderPro 110K gives you plenty of power for larger copper enamel pieces

This larger piece of copper required more heat to get it to the right temperature for enameling, but the SolderPro 110K was easily able to supply the power required. The SolderPro 110K gas soldering iron has a continuous heat adjustment lever that enables you to adjust the gas flow very easily even in the middle of a job.

Enameling success with the Iroda SolderPro 110K gas soldering iron

We were very happy with how well the enameling worked with the Iroda SolderPro 110K gas soldering iron in gas torch configuration and impressed with how quickly we could complete these enameling jobs with this easy to use, portable, gas torch.

The Iroda SolderPro 110K gas soldering iron is a versatile tool for enameling as well as soldering projects

Iroda Professional gas soldering irons deliver pinpoint precision heat with plenty of power for jewelry enameling. Of course, the Iroda SolderPro 110K is also excellent for soldering work, but the high power output and smooth heat control make it a handy tool for any project where you need to be able to accurately apply heat without worrying about maintaining control.

Find the Iroda SolderPro 110K on Amazon, where as well as working perfectly as a gas torch, you’ll find it comes with a heat gun tip and heat shield for heatshrink connections and heatshrink insulation work as well as a carving tip for plastics and, of course, solder and a solder tip suitable for all sorts of soldering connections.