Part 1: Heat Shrinking Electrical Wiring

What is Heat Shrink for Electrical Wiring?

Heat shrink tubing is a polymer that shrinks radially when heated, used for electrical insulation, wire splicing, and protecting connections from damage.

Applications of Heat Shrink for Electrical Wiring

- Electrical Insulation: Provides insulation for wires, connections, joints, terminals, and splices.

- Environmental Protection: Shields connections from moisture, dust, and other elements.

- Mechanical Protection: Guards against abrasion and physical damage.

- Organizational Uses: Bundles and organizes wires.

Tools for Heat Shrinking Electrical Wiring

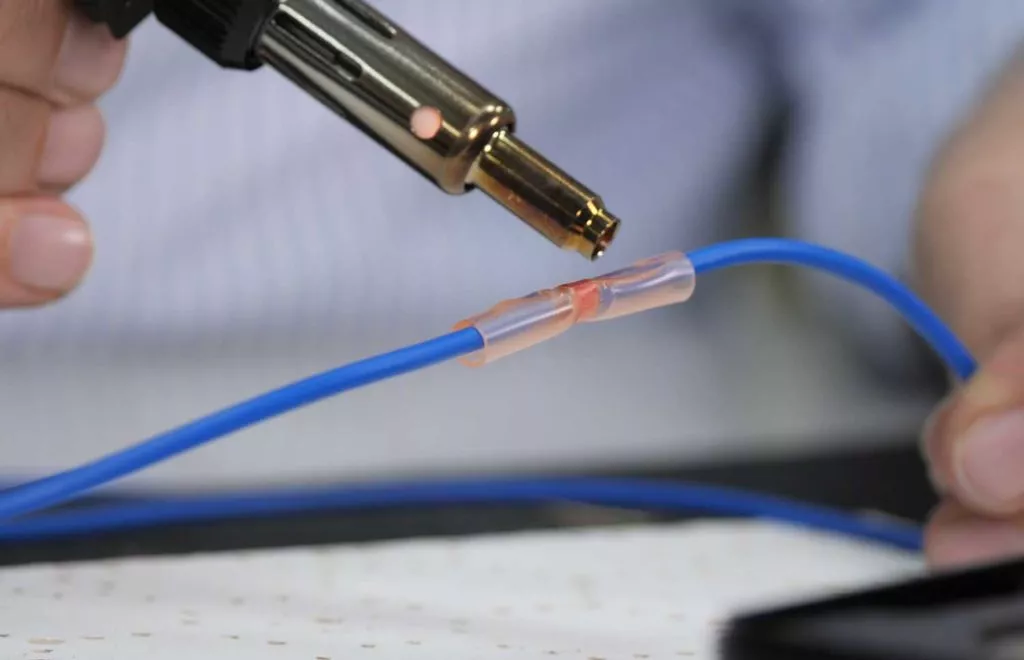

For electrical wiring, tools like the Pro-Iroda SOLDERPRO 90 , MJ-950 and MJ-600 are ideal. These butane soldering irons come with hot air blower tips, perfect for precision heat shrinking tasks.

Steps for Using Heat Shrink Tubing on Electrical Wiring

- Select the Right Size: Choose a heat shrink tube with a diameter that fits snugly over the area to be covered.

- Cut the Tube: Cut to the desired length, ensuring full coverage of the connection or splice.

- Position the Tube: Slide the tube over the area.

- Apply Heat: Use a hot-air gun or heat gun to apply heat evenly around the tubing. Move the heat source consistently to avoid overheating.

- Cool Down: Allow the tubing to cool and contract fully, forming a tight seal.

Benefits of Using Heat Shrink for Electrical Wiring

- Durability: Long-lasting protection for electrical connections.

- Insulation: Excellent electrical insulation reduces the risk of shorts.

- Waterproofing: Creates waterproof seals for outdoor or damp environments.

- Versatility: Available in various sizes and colors, suitable for multiple applications.

Part 2: Heat Shrinking Large-Scale Applications

What is Heat Shrink for Large-Scale Applications?

Heat shrink materials are also used for larger applications, such as plastic wrapping and protecting bulkier items.

Applications of Heat Shrink for Large-Scale Applications

- Plastic Wrapping: Protects large items during shipping or storage.

- Environmental Protection: Shields bulkier items from moisture, dust, and other elements.

- Mechanical Protection: Provides a protective layer for larger objects, preventing damage.

Tools for Heat Shrinking Large-Scale Applications

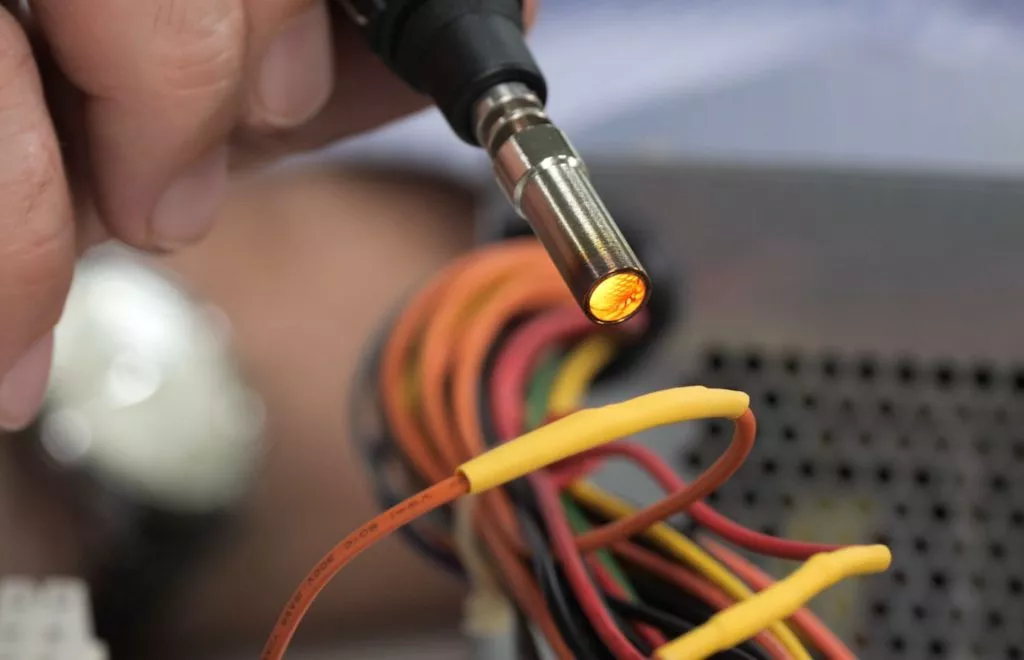

For larger applications, Iroda’s butane heat guns like the HG-350 are the perfect choice. They provide high heat and quick performance, essential for efficient large-scale heat shrinking.

Steps for Using Heat Shrink for Large-Scale Applications

- Select the Right Material: Choose a heat shrink material that fits over the large item you need to cover.

- Cut the Material: Measure and cut the material to the required size, ensuring full coverage.

- Position the Material: Place the material over the item to be protected.

- Apply Heat: Use a butane heat gun to apply heat evenly over the material. Ensure uniform heat distribution to avoid uneven shrinkage.

- Cool Down: Allow the material to cool and contract fully, forming a tight and protective seal.

Benefits of Using Heat Shrink for Large-Scale Applications

- Durability: Provides robust protection for large items.

- Waterproofing: Ensures items are protected from moisture and other environmental factors.

- Efficiency: Quick and effective heat shrinking process with high-performance tools.

Heat shrinking is essential for securing and insulating both electrical connections and larger items. With the right tools, such as Pro Iroda’s range of heat guns and soldering kits, you can achieve professional results in any heat shrinking project. Explore Pro Iroda’s products to find the perfect tool for your needs and elevate your heat shrinking applications.

FAQ – Heat Shrink Tubing

Explore More

Discover the full range of Pro Iroda heat guns and soldering kits on our website and enhance your heat shrinking projects with professional-grade tools.

Electric Heat Gun?

If a butane powered heat gun is not practical for your requirements, you can also select our cordless hot air tools powered by lithium ion battery.